Key Takeaways

- What Is Memory Foam: Memory foam is a type of polyurethane foam that has been treated with additional chemicals to enhance its density and viscosity. The foam responds to body heat, softening in areas where it comes into contact with the body, which allows it to mold itself to the individual’s shape and evenly distribute weight, providing pressure relief.

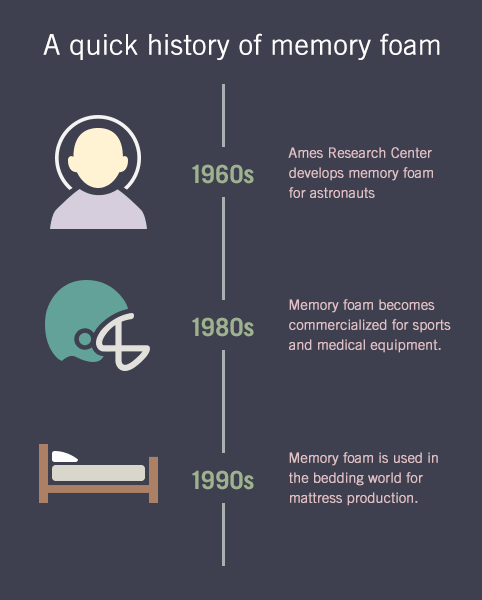

- Where Memory Foam Came From: Memory foam mattresses are a product of NASA’s space program, developed at the Ames Research Center in the 1960s. The material found practical applications on Earth, particularly in medical and sports equipment. In the 1980s, the formula and rights for memory foam were released to private companies, leading to its introduction in bedding.

- Manufacturing of Memory Foam: The manufacturing process of memory foam involves mixing ingredients like polyols and isocyanates, whipping the mixture into a froth, infusing it with gas or vacuum sealing to create an open-cell structure, cooling and curing the foam, washing it to remove residues, cutting it into pieces, and assembling it into a finished mattress.

Have you ever wondered how memory foam becomes, well, memory foam? From its origins with NASA to modern production, the answer to how a memory foam mattress is made involves a sequence of high-tech manufacturing processes.

The process is similar to other foams, but with a few important changes that produce the unique characteristics of visco-elasticity. Keep reading to learn where memory foam comes from, and how it’s made.

Best Amerisleep Memory Foam Mattresses

Quick Guide: A 30-Second Summary

| Best Memory Foam Mattress Overall | Amerisleep AS3 |

| Best Firm Memory Foam Mattress | Amerisleep AS2 |

| Best Soft Memory Foam Mattress | Amerisleep AS5 |

Origins of Memory Foam

Memory foam is the technological brainchild of NASA’s space program. It was developed at the Ames Research Center in the 1960s, contracting with NASA at the time to produce a material that would effectively minimize the extensive pressure on astronauts’ bodies cause by G-forces during takeoff and reentry.

Memory foam is the technological brainchild of NASA’s space program. It was developed at the Ames Research Center in the 1960s, contracting with NASA at the time to produce a material that would effectively minimize the extensive pressure on astronauts’ bodies cause by G-forces during takeoff and reentry.

For a few reasons, NASA never implemented memory foam, which they also called temper foam, in space shuttles. However the organization did recognize the potential practical applications here on earth and began commercializing it in partnership with Dynamic Systems in medical and sports equipment.

In the 1980s, the formula and rights for memory foam were released to Fagerdala World Foams, one of the first private companies to work with the foam. This was the company that would introduce memory foam to bedding, with the introduction of the Tempur-Pedic® mattress in 1991.

Since that time, many other mattress manufacturers have developed memory foam, changing and improving on the process to meet consumer demands.

Memory Foam and Polyurethane Foam

Polyurethane foam is the precursor to memory foam, and has a fascinating history dating back to the 1950s. During its production, various substances such as water, halocarbons, or hydrocarbons are added to a polyurethane mix. This versatile material has found its way into numerous applications, ranging from car parts to spray liners.

The distinctive feature of memory foam lies in its ability to conform to the body’s contours, providing exceptional support and pressure relief. When you lie on a memory foam mattress, the foam responds to your body heat, softening in the areas where it comes into contact with your body.

This allows the resulting foam to mold itself to your unique shape, evenly distributing your weight and alleviating pressure points. As you change positions during sleep, the foam gradually adjusts and supports your new posture, ensuring continuous comfort throughout the night.

The open cell structure of memory foam also promotes airflow, contributing to its temperature-regulating properties. Unlike traditional mattresses that may trap heat, memory foam allows air to circulate within the foam, dissipating excess warmth and keeping you cool and comfortable. This enhanced breathability can be particularly helpful for hot sleepers or for those living in warmer climates.

It’s important to note that memory foam is just one type of foam, specifically designed to offer optimal comfort and support. While it shares a common origin with polyurethane foam, memory foam undergoes additional processing steps to achieve its unique properties. These modifications allow memory foam to excel in providing a luxurious sleep experience, making it a popular choice for those seeking exceptional comfort and pressure relief.

How a Memory Foam Mattress is Made

The production of memory foam is a true marvel of modern chemistry and industry. Memory foam is made by reacting different substances in a process similar to polyurethane, but with additional agents that create the viscous, denser properties inherent to memory foam. Here is the basic process involved in its production:

Step 1: Mixing Ingredients

Polyols (alcohols derived from petroleum products or plant oils), isocyanates (organic amine-derived compounds) and reacting agents are mixed together right before production.

Polyols (alcohols derived from petroleum products or plant oils), isocyanates (organic amine-derived compounds) and reacting agents are mixed together right before production.

Reacting agents, also known as catalysts, are substances that facilitate and control chemical reactions without being consumed in the process. They are added to a reaction to increase the rate of the reaction or modify its outcome.

Step 2: Whipping Ingredient Mixture

This memory foam mixture is then whipped into a froth and poured into a mold. An exothermic, or heat-releasing, reaction is the result, which causes the mixture to bubble up and produce foam.

This memory foam mixture is then whipped into a froth and poured into a mold. An exothermic, or heat-releasing, reaction is the result, which causes the mixture to bubble up and produce foam.

Step 3: Infusion or Vacuum Sealing

The foamy mixture may be infused with gas or blowing agents, which expands the mixture’s cellular structure to create foam. Traditionally, ozone-depleting chlorofluorocarbons were used as a blowing agent, but nowadays many manufacturers use eco-friendly and nontoxic blowing agents like water.

The foamy mixture may be infused with gas or blowing agents, which expands the mixture’s cellular structure to create foam. Traditionally, ozone-depleting chlorofluorocarbons were used as a blowing agent, but nowadays many manufacturers use eco-friendly and nontoxic blowing agents like water.

Or the foam mixture may be vacuum-sealed to create the open-cell matrix. The amount of polymer mixture versus air correlates to the resulting density.

Step 4: Cooling and Curing

At this stage, the large chunk of foam is referred to as a “bun”. The bun is then cooled, and heated again after which it is left to cure, which can take anywhere from 8 hours to a few days.

At this stage, the large chunk of foam is referred to as a “bun”. The bun is then cooled, and heated again after which it is left to cure, which can take anywhere from 8 hours to a few days.

Step 5: Washing Memory Foam

After curing the memory foam is inert (no longer reactive). The material may be washed and dried to remove lingering residues, and can now be inspected for quality.

After curing the memory foam is inert (no longer reactive). The material may be washed and dried to remove lingering residues, and can now be inspected for quality.

Step 6: Cutting Memory Foam

Once the memory foam bun is finished, it is then cut into pieces for use in mattresses and other products. The mattress-sized pieces are now ready to be assembled into a finished bed.

Once the memory foam bun is finished, it is then cut into pieces for use in mattresses and other products. The mattress-sized pieces are now ready to be assembled into a finished bed.

Step 7: Assembling the Memory Foam Mattress

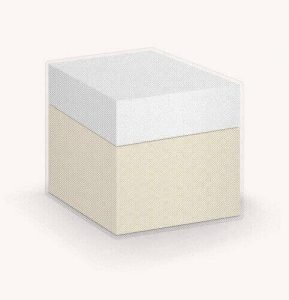

Memory foam mattress assembly usually involves a few basic steps. The base of every memory foam mattress is regular polyurethane, which is referred to as the “core” or support layer. The actual memory foam layers and any other padding layers in between are set above the core, and attached to one another using adhesive (which will vary by manufacturer).

Memory foam mattress assembly usually involves a few basic steps. The base of every memory foam mattress is regular polyurethane, which is referred to as the “core” or support layer. The actual memory foam layers and any other padding layers in between are set above the core, and attached to one another using adhesive (which will vary by manufacturer).

The entire mattress is then covered with a flame resistant fabric barrier sock to meet federal safety regulations (manufacturers may also use spray chemicals or mix additives in with the foam to achieve fire resistance as well). Fiberglass was once common, but many shoppers now seek fiberglass-free mattresses.

Once a mattress flame retardant is added, the mattress then receives a finished cover to complete its appearance. Ideally, the material also works with the memory foam layer for maximum comfort.

Readying the Finished Mattress For Shipping

At Amerisleep, once the finished memory foam mattress is ready, it is then vacuum-sealed, compressed, rolled and packaged. We make our mattresses in box to order, ensuring that you receive a mattress that’s seen as little wear and tear as possible.

At Amerisleep, once the finished memory foam mattress is ready, it is then vacuum-sealed, compressed, rolled and packaged. We make our mattresses in box to order, ensuring that you receive a mattress that’s seen as little wear and tear as possible.

This method allows the mattress to ship via regular courier rather than freight, which reduces fuel consumption. The compressed size also makes it easier to move the boxed mail order mattress into your home.

Different Types of Memory Foams

When it comes to memory foam, there are different types available on the market, each with its own unique characteristics and properties. These variations in memory foam can be attributed to differences in the manufacturing process and the specific materials used. Let’s explore some of the different types of memory foam

Traditional Memory Foam

Traditional memory foam, also known as viscoelastic foam, is the classic and most widely recognized type. It is made from a polyurethane material that has been treated with additional chemicals to enhance its density and viscosity.

Traditional memory foam has a slow response time, meaning it takes a bit longer to regain its original shape after pressure is applied and released. This characteristic allows it to conform closely to the body, providing excellent support and pressure relief.

Gel Memory Foam

Gel-infused memory foam incorporates gel particles or beads into the foam material. The addition of gel helps to regulate temperature by dissipating heat more effectively than traditional memory foam. This can be particularly beneficial for individuals who tend to sleep hot or for those who live in warmer climates.

Gel-infused memory foam retains the contouring and pressure-relieving properties of traditional memory foam while offering improved cooling properties.

Plant-Based Memory Foam

Plant-based memory foam is an eco-friendly alternative to traditional memory foam. It is made by replacing a portion of the petroleum-based ingredients with plant-derived materials, such as soybean oil or castor oil.

This results in a memory foam that has a reduced environmental impact and may have a lower odor compared to traditional memory foam. Plant-based memory foam typically retains the supportive and contouring properties of traditional memory foam.

Copper Infused Memory Foam

Copper-infused memory foam is most similar to gel memory foam, as it incorporates tiny particles of copper into the foam material. Copper has natural antimicrobial properties and can help inhibit the growth of bacteria and allergens. This makes it a hygienic choice for hypoallergenic mattresses.

Plus, copper-infused memory foam may offer some thermal conductivity, potentially aiding in temperature regulation.

More Types of Mattresses

It’s important to note that while memory foam mattresses have their own unique characteristics, other mattress types like latex, hybrid, and innerspring mattresses offer different sleep experiences. The choice between these mattress types depends on individual preferences, comfort needs, and factors like desired support, motion isolation, and temperature regulation.

Latex Mattresses

Latex mattresses are made from natural or synthetic latex foam. Natural latex is derived from rubber tree sap, while synthetic latex is created using chemical processes not unlike memory foam.

Latex mattresses are made from natural or synthetic latex foam. Natural latex is derived from rubber tree sap, while synthetic latex is created using chemical processes not unlike memory foam.

Latex mattresses are known for their responsiveness, durability, and excellent support. They offer a bouncy and buoyant feel, contouring to the body’s curves while still providing a supportive surface. Latex mattresses are also naturally breathable and hypoallergenic.

Hybrid Mattresses

Hybrid mattresses combine the benefits of memory foam or latex with the support of innerspring coils. These mattresses typically feature multiple layers, including a comfort layer of memory foam or latex and a support layer of pocketed coils.

Hybrid mattresses combine the benefits of memory foam or latex with the support of innerspring coils. These mattresses typically feature multiple layers, including a comfort layer of memory foam or latex and a support layer of pocketed coils.

The combination of materials aims to provide the best of both worlds: the pressure relief and contouring of foam or latex and the support and responsiveness of coils. Hybrid mattresses are suitable for those seeking a balance between comfort and support.

Innerspring Mattresses

Innerspring mattresses are the traditional and most widely recognized type of mattress. They consist of a support system made of metal coils or springs, with a layer of padding on top for comfort.

Innerspring mattresses are the traditional and most widely recognized type of mattress. They consist of a support system made of metal coils or springs, with a layer of padding on top for comfort.

Traditional innerspring mattresses offer a responsive and bouncy feel, with varying levels of firmness depending on the coil design and the type and thickness of the comfort layers. They are known for their excellent breathability, allowing for good airflow to keep the mattress cool.

Air Mattresses

Air mattresses, also known as inflatable mattresses, are versatile sleep surfaces that use adjustable air chambers for support. They can be easily inflated and deflated, making them convenient for camping or temporary use. However, comparing air mattresses to memory foam mattresses, this mattress type may lack the same level of contouring and pressure relief.

Air mattresses, also known as inflatable mattresses, are versatile sleep surfaces that use adjustable air chambers for support. They can be easily inflated and deflated, making them convenient for camping or temporary use. However, comparing air mattresses to memory foam mattresses, this mattress type may lack the same level of contouring and pressure relief.

Additionally, they may require regular inflation adjustments and are more prone to sagging or developing leaks over time.

Frequently Asked Questions

Is memory foam safe for humans?

Yes, memory foam is generally safe for humans. Memory foam is made using polyurethane, which is a common material used in various household products. However, it’s important to note that some individuals may be sensitive to certain chemicals or experience off-gassing when the mattress is new.

To ensure safety, we adhere to strict manufacturing standards and regulations to minimize potential health risks. All of our polyurethane foams are CertiPUR-US® certified, which means our foam is verified as free of PBDEs, TDCPP or TCEP (“Tris”) flame retardants, ozone depleters, heavy metals, and formaldehyde.

What is the main ingredient in memory foam?

The main ingredient in most memory foam mattresses is polyurethane. Our team carefully selects and combines polyols (polyester or polyether polyols) and diisocyanates to create a chemical reaction that forms the foam structure. This combination of ingredients results in the unique properties of memory foam, including its ability to contour to the body and provide pressure relief.

At Amerisleep, we also replace select petrochemical products with castor oil, creating our Bio-Pur® foam that is more responsive and cooler than traditional memory foam.

Is memory foam a natural material?

Memory foam is not considered a natural material. It is primarily made from synthetic components, including polyurethane foam, which is derived from petroleum-based products. However, advancements have been made in the industry to create more eco-friendly versions of memory foam by incorporating plant-based ingredients or using cleaner manufacturing processes.

Our Bio-Pur® foam is one such foam, designed for sustainability as much as durability and comfort. And we continuously explore greener alternatives to reduce the environmental impact of our products.

Why can’t you wash memory foam?

Due to its porous structure, memory foam absorbs liquids and moisture, making it difficult to fully dry. This moisture retention can lead to the growth of mold or mildew and bacteria within the foam, compromising its integrity and potentially causing health issues. Instead of washing, we suggest a mattress protector to cover the memory foam surface and keep it clean.

Spot cleaning the surface with a mild detergent and water solution may be appropriate for small stains or spills, but excessive moisture should be avoided. You can freshen up a memory foam mattress without using liquid cleaners by sprinkling baking soda over the surface.

Does memory foam hold bacteria?

Memory foam itself is not a hospitable environment for bacteria to thrive. The dense structure of the foam limits the growth and multiplication of bacteria. However, like any other sleep surface, it can accumulate dust, dead skin cells, allergens, and other contaminants over time.

Using a mattress protector can keep particles from collecting and provide an additional layer of protection against bacteria in the bed and things that promote bacteria growth, such as moisture from sweat or spills. Regular cleaning through vacuuming and airing out the mattress can further help keep it fresh and hygienic.

The Bottom Line

The production of memory foam beds is a complex process that has been improved and perfected over the past 40-plus years. Since the introduction of pressure-relieving memory foam mattresses 20 years ago, the category has continued gaining popularity with consumers due to the unparalleled pressure relief and supportive benefits it offers.

These unique properties are the result of a time-intensive, complex process that is as interesting as the final product. Now you know the basics of how memory foam mattress manufacturing works, from its beginnings in chemistry to its arrival on your doorstep!

About the author

Geoff McKinnen is a writer focusing mainly on the healthcare industry and has written articles on everything from foods to help you lose weight to the connection between Alzheimer’s and sleep. Geoff’s passionate about helping readers improve their well-being to lead happier lives. Outside of work, Geoff enjoys cycling and hiking and believes that by leading a healthy lifestyle, he can help others do the same.

View all posts